Bronze strip and bronze semi-finished products manufacturer from Germany

We offer strips in 11 different bronze alloys.

Strip product: Buy bronze strip and semi-finished products from Germany

Bronze strip is used in industry for a variety of applications. Here are some typical applications:

1. Mechanical engineering

Mechanical engineering: In this industry, bronze strip is used to make machine parts such as bearings, bushings and gears. Bronze is well suited for such applications due to its high wear resistance and low coefficient of friction.

2. Electrical industry

Electrical industry: Bronze strip is also used for electrical applications such as contacts, switches and relays. It has good electrical conductivity and is resistant to corrosion, which promotes its use in this industry.

3. Automotive industry

Automotive industry: In this industry, bronze strip is used for the production of parts such as connecting rods, piston rings and valve components.

4. Construction industry

Construction industry: Bronze strip is often used in the construction industry for applications such as door and window fittings or also for gutters and downpipes.

5. Arts and crafts

Arts and crafts: Bronze ribbon is also a popular material in arts and crafts, where it is used to make jewellery, statues and other decorative objects.

6. Musical instruments

Musical instruments: Many musical instruments, especially wind instruments such as trombones and saxophones, are also made from bronze strip.

7. Ammunition

Ammunition: Here, bronze strip is also used to make casings for firearm ammunition.

Applications of bronze (copper-tin alloys) BB20 | BB21

Bronze strip grades BB20 and BB21 are special types of bronze alloys suitable for various industrial purposes. They can be used for the following applications:

Plain bearings: These strips are often used in plain bearings used in various machines and equipment.

Bushings: Bronze strip grades BB20 and BB21 are used for the production of bushings, which are required in many industrial applications.

Automotive: These strips are also used in various components in the automotive sector – for example in gearboxes, brakes and steering systems.

Mechanical engineering: BB20 and BB21 are used in various mechanical engineering parts such as gears, shafts, bearings and the like.

Shipbuilding: In ships, they are used to make pumps and valves.

Electrical industry: BB20 and BB21 bronze strips are used in electrical contacts and connectors.

The choice between BB20 and BB21 depends on the specific requirements of the application, such as the strength and corrosion resistance needed.

Applications of bronze (copper-tin alloys) BB40 | BB40 Plus | BB50 | BB60 | BB60 Plus | BB80 | BB80 Plus | BB95

Bronze strip grades BB40, BB40 Plus, BB50, BB60, BB60 Plus, BB80, BB80 Plus and BB95 are special bronze alloys used for various applications and in different industrial sectors. Here are some of their typical applications:

Plain bearings and bushings: Similar to BB20 or BB21, these bronze strip grades are often used to make plain bearings and bushings, which are needed in many different machines and devices.

Automotive: They are used in the automotive industry in parts such as gearboxes, brakes, steering systems as well as other automotive components.

Mechanical engineering: These bronze strips are used to make various machine parts – for example gears, shafts and bearings.

Shipbuilding: The aforementioned bronze strip grades are used in the production of ship components, including pump parts and valves.

Electrical engineering: Some of these bronze strips are also used in electrical engineering to make electrical contacts and connectors.

The specific choice of bronze strip grade depends on the requirements of the application, including factors such as the strength, hardness and corrosion resistance required.

Copper-base-alloys

Bronze

Available dimensions of bronze strip

Bronze strips are available from Sundwiger Messingwerk in various dimensions.

For example, you can get bright pre-rolled strip in widths from 1.0 to 5.0 millimetres or precision strip thicknesses from 0.07 to 1.2 millimetres. Strip widths from 3.0 to 600 millimetres are also available.

You can find some common dimensions in the clear tables below.

However, we recommend that you contact us on this subject and enquire directly about the specific dimensions that can be supplied. We are always ready to inform you in detail about this.

- Bright pre-rolled strip

1,0 – 5,0 mm - Precisions strip thicknessess

0,07 – 1,2 mm - Strip widths

3,0 – 600 mm,

but at least 10 times strip thickness

Bronze (copper-tin) BB20 | BB21| BB40 | BB40 Plus | BB50 | BB60 | BB60 Plus | BB80 | BB80 Plus | BB95

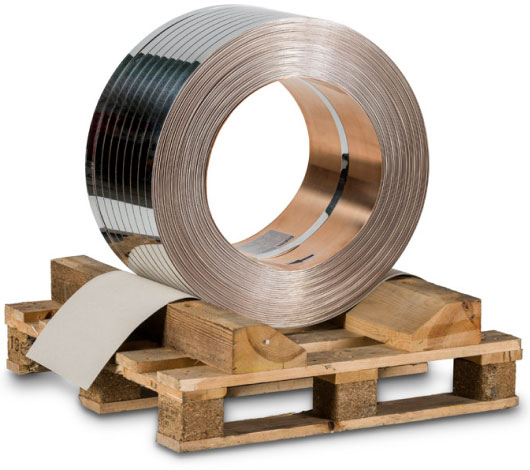

Bronze ribbon in various delivery presentations directly from the factory

The delivery form of our products depends on the technical equipment of our customers. Three basic versions are available. These are adapted to your existing facilities.

The most used form are coils. Here, the individual coils are stacked on pallets, usually separated by spacers.

In the spooled version, several coils are wound in one spool. The coils are connected with help of a weld seam. In this way, set-up times can be saved in the subsequent process steps.

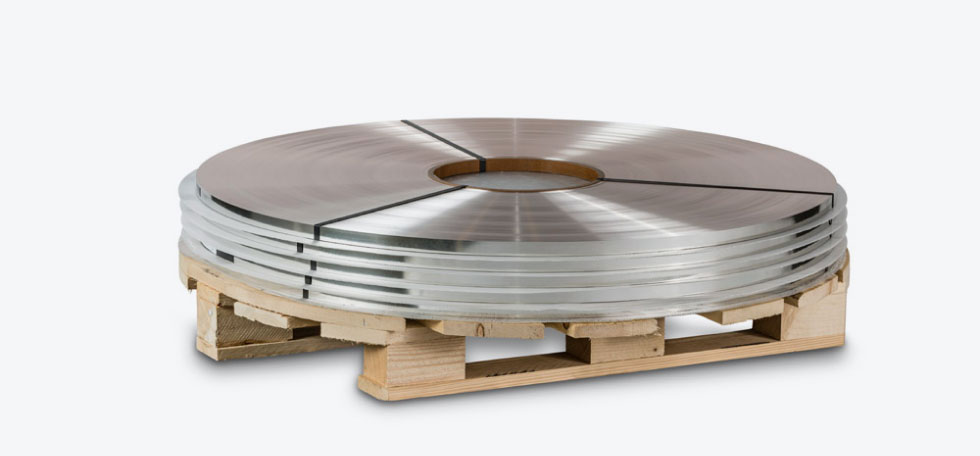

Multiple Pancake

Multiple pancake is a special form of coil design. Here, the individual coils are connected alternately at the inner and outer windings by weld seams. The created “endless strip” can be unwound directly from the pallet on turntables.

Bronze strip FAQ: Frequently asked questions about our copper-tin alloy

How do the various bronze grades (copper-tin alloys) BB20 | BB21 | BB40 | BB40 Plus | BB50 | BB60 | BB60 Plus | BB80 | BB80 Plus | BB95 differ?

The aforementioned bronze grades BB20, BB21, BB40, BB40 Plus, BB50, BB60, BB60 Plus, BB80, BB80 Plus and BB95 differ primarily in terms of their composition, hardness and strength. These are different alloys of bronze with copper as the base material. The difference lies mainly in different amounts of tin and other metals in the alloys.

The numbers after “BB” usually indicate the tin content in the alloy. For example, BB20 has a low tin content, while BB95 has a high tin content. A higher tin content usually increases the hardness and strength of the bronze.

The grades with the suffix “Plus” have improved performance in terms of wear resistance or friction properties. This is achieved through additional alloying elements or special heat treatments.

The actual differences in hardness, strength, wear resistance and other properties may vary depending on the specific alloy. It is therefore important to consult the technical data sheets of the individual bronze grades to understand the exact differences and properties.

BB20: BB20 is a bronze alloy containing 2 percent tin and an iron addition of 0.1 percent. This alloy is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

BB21: BB21 is a bronze alloy containing 2 percent tin, 2.2 percent zinc and 0.1 percent iron. This alloy is characterised by a particularly good combination of strength, electrical conductivity and metal value. It is often used for connectors and current-carrying springs in contacts.

BB40: BB40 is a bronze alloy containing 4 percent tin. This alloy is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

BB40 Plus: The so-called eco-bronze BB40 Plus is a modified bronze alloy that contains 4 percent tin. This alloy is characterised by a very fine microstructure. In addition, this bronze grade has significantly higher strength and ductility as well as very high electrical conductivity. It is mainly used for miniature connectors and current-carrying springs in contacts.

BB50: BB50 is a bronze alloy containing 5 percent tin. This alloy is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

BB60: BB60 is a bronze alloy containing 6 percent tin. This alloy is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

BB60 Plus: The eco bronze BB60 Plus is a modified 6-percent tin bronze that is characterised by a very fine microstructure. This alloy has high strength and ductility as well as very high electrical conductivity. It is mainly used for miniature connectors and current-carrying springs in contacts.

BB80: BB80 is a bronze alloy with a tin content of 8 percent. This alloy is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

BB80 Plus: BB80 Plus is a modified bronze alloy with 8 percent tin. This alloy is characterised by a very fine microstructure with a significantly higher strength. At the same time, this bronze grade has a greatly improved ductility as well as bendability compared to a conventional 8 percent tin bronze. It is mainly used for miniature connectors and current-carrying springs in contacts.

BB95: BB95 is an innovative bronze alloy with 10 percent tin content. This bronze grade was specially developed to meet the requirements of miniaturisation. BB95 is characterised by a particularly good combination of strength and electrical conductivity. It is often used for connectors and current-carrying springs in contacts.

What are the special features of bronze (copper-tin alloy)?

Copper and tin together form a material called tin bronze – an alloy with many advantages. Because tin bronze has some special properties, it is used in various areas.

Resistance: Tin bronze is hard and resistant to wear. This makes it suitable for parts that have to withstand a lot.

Good electrical conductivity: Tin bronze conducts electricity very well, which makes it ideal for electrical contacts and connections.

Corrosion resistance: Tin bronze is corrosion resistant to air, water and many chemicals. This is due to the component tin, which protects the bronze.

Low coefficient of friction: Tin bronze has low friction. This is ideal for bearings and rails that need to move easily.

Low melting point: Due to its low melting point, the processing of tin bronze is simplified. Good casting properties: Tin bronze is easy to cast, which enables the production of complicated and precise shapes.

Processing instructions of BB20 | BB21 | BB40 | BB40 Plus | BB50 | BB60 | BB60 Plus | BB80 | BB80 Plus | BB95

| Processing instructions | |

| Cold forming properties | very good |

| Machinability | sufficient |

| Electroplating properties | very good |

| Hot-dip 3nning properties | very good |

| Soldering | very good |

| Resistance welding | good |

| Gas shielded arc welding | good |

| Laser welding | very good |

What does the production process of the bronze ribbon look like?

The bronze strip production process may well vary somewhat, based on specific product requirements and the exact alloy composition. However, here are basic steps that are usually involved:

Melting: First, the bronze alloy components are mixed in a melt. Other elements are also added to achieve specific properties.

Casting: The melt is then poured into a specific mould.

Rolling: Our production plant has three rolling stands, which gives us a high rolling capacity: It enables us to meet even the strictest rolling tolerances according to Sundwiger’s fine tolerance standards. Furthermore, our two 20-high rolling stands enable us to achieve very thin material thicknesses precisely and with extremely tight tolerances.

Heat treatment: The rolled strip undergoes heat treatment to improve its mechanical properties as well as to reduce stresses in the material.

Cutting: The strip is then cut to the desired width (slitting) and wound onto rolls.

Are the surfaces of the strips hot-dip tinned and electroplated?

In addition to the physical and technological properties of the basic material bronze, Sundwiger Messingwerk also offers surfaces with hot-dip tinning as well as galvanic coating in its extensive product portfolio in the area of flat products.

Hot-dip tinning is of great importance in many technical applications, as it plays an important role in the use of metallic materials. In addition to protection against corrosion, tin plating enables secure contacting in plug-in connections and improves solderability. Hot-dip tinned surfaces naturally form intermetallic phases, making them largely resistant to the occurrence of whisker effects, which often cause failures of electrical components, even without further post-treatment.

In addition to hot-dip tinning, Sundwiger Messingwerk offers a wide range of electroplated coatings. These techniques are used when tight tolerances for coating thickness or a combination of different coatings are required. The coating layer of the tin or nickel plated strips is uniform, covers the entire surface and has either a matt or shiny appearance.

What do I have to bear in mind when working with bronze strip?

The following processing methods can be used for bronze strip under certain conditions:

Cold forming: Bronze strip can only be cold formed to a limited extent. The preferred method for processing bronze is actually hot forming. With cold forming, the material is more prone to cracking and breaking. It is possible to cold form a very thin bronze strip, but it requires care and the right tooling to avoid damage. For complex shapes, it is usually necessary to heat the bronze strip to make it more flexible.

Machining: Bronze is one of the materials that can be machined well. However, we recommend using only high-quality tools and checking them regularly. In addition, when machining bronze, use a suitable cutting fluid to reduce tool wear.

Electroplating: In general, bronze strip can be electroplated, but the process is more complex than for other metals. Electroplating bronze is generally not done as often because bronze is naturally corrosion resistant and is often chosen for its unique appearance, which electroplating inevitably alters. In addition, the chemicals used in electroplating can attack the bronze and cause discolouration or damage.

Immersion tinning: Immersion tinning of bronze strip is generally well feasible. However, interdiffusion can occur between tin and bronze, which can lead to a change in properties. Therefore, an intermediate layer, for example of nickel, is often applied.

Soft soldering: In soft soldering, temperatures of below 450 degrees Celsius are reached, which is well suited for bronze. The surface of the bronze strip should be clean and free of oxides to ensure good adhesion between the solder and the material.

Resistance welding: In principle, bronze can be joined by resistance welding. However, the material has a rather high thermal conductivity, which makes the process more difficult. Higher amperages and strict control of parameters are essential to achieve a good weld. The weldability also depends on the specific bronze alloy.

Gas-shielded welding: It is quite possible to weld the bronze strip with shielding gas. However, it requires a high degree of experience and skill, as bronze melts and burns quickly at high heat. Proper welding equipment is therefore of great importance in order to achieve an optimal result.

Laser welding: The bronze strip can be laser welded quite well. The process allows a very precise and clean machining of the material. However, the result may vary depending on the specific alloy of the bronze. Certain technical conditions may therefore be required to achieve the optimum welding result.

We advise you on our bronze strip copper base alloys

Call us or write to us, we will be happy to advise you personally!

Contact Form

Write to us, we would be happy to advise you personally!

About Sundwiger Messingwerk

For more than three centuries, Sundwiger Messingwerk has been a market leader in Germany in the manufacture of high-quality copper-based alloy products, including bronze strip and other semi-finished bronze products. In addition to standardised solutions in the area of strip products, we also offer the adaptation of our products and their properties to individual customer requirements.

As a certified company, our top priorities are the consistently high quality of our products and effective process control. We are continuously working on the improvement and further development of our production processes and offer you maximum safety and reliability.

Sundwiger Messingwerk attaches great importance to customer satisfaction and long-term business relationships. We do our utmost to provide you with the highest level of performance and services. Contact us today and let us discuss your individual requirements and technical conditions together.

Sundwiger-Messingwerk: We produce bronze strip and other bronze semi-finished products

Sundwiger Messingwerk is a certified company and places great emphasis on the continuous improvement of its products and processes. Our products meet the highest quality standards and are manufactured according to strict specifications.

Our range of bronze strip and other semi-finished bronze products includes various alloys. The different bronze grades have different properties and can therefore be used for different applications. Our experienced team will be happy to advise you on the right alloy for your application.

We are proud to offer you our high quality products and excellent customer service. If you need a high quality bronze strip, contact us – we are your partner for customised solutions in strip products.