Fine alloyed strip and semi-finished products

We offer strips in 3 different fine alloys.

Buy strip product and semi-finished products with fine alloys from Germany

Applications of fine alloys BB01 | SB01 | SB02

Typical applications

- Age-hardenable alloys for connectors and power transistor carriers and semiconductor devices

- Leaf springs for relays

- Stamped-bent parts

- Transistor carriers

- Connector pins

- Carriers

- Car electrics

Copper-base-alloys

Available dimensions of strip with fine alloys

- Bright pre-rolled strip

1,0 – 5,0 mm - Precisions strip thicknessess

0,07 – 1,2 mm - Strip widths

3,0 – 600 mm,

but at least 10 times strip thickness

Fine alloys BB01 | SB01 | SB02

Fine alloys in various delivery presentations directly from Sundwiger Messingwerk

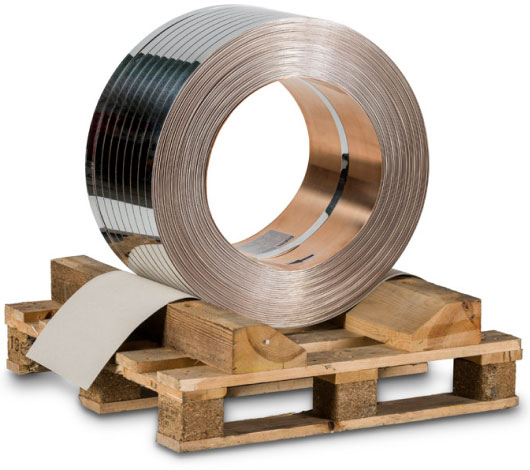

The delivery form of our products depends on the technical facilities of our customers. Three basic designs are available here. These are each adapted to the equipment available at our customers.

The most used form are coils. Here, the individual coils are stacked on pallets, usually separated by spacers.

In the spooled version, several coils are wound in one spool. The coils are connected with help of a weld seam. In this way, set-up times can be saved in the subsequent process steps.

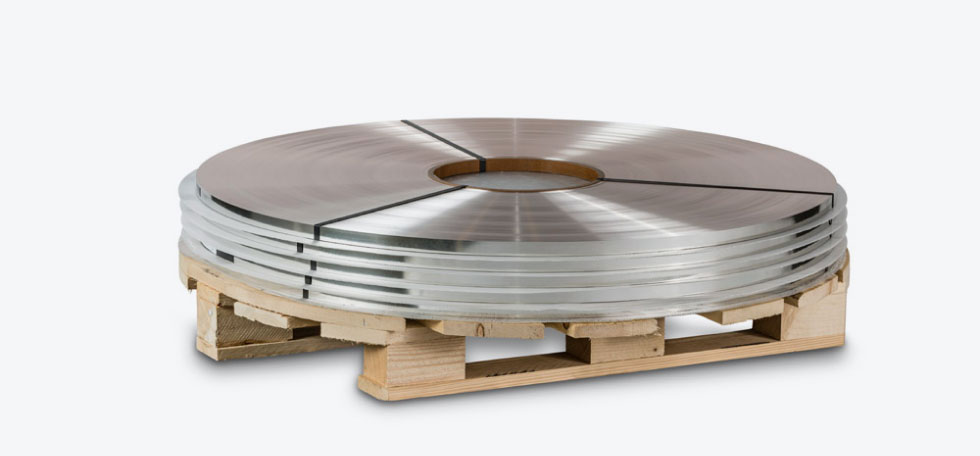

Multiple Pancake

Multiple pancake is a special form of coil design. Here, the individual coils are connected alternately at the inner and outer windings by weld seams. The created “endless strip” can be unwound directly from the pallet on turntables.

Frequently asked questions about our products with fine alloys

What are the special features of the fine alloys BB01 | SB01 | SB02?

BB01: Low-alloyed copper alloys are distinguished by a high electrical conductivity. They do not reach the spring force of the bronzes, however, in comparison with pure copper, they are significantly harder. Therefore, they are predominantly used for lead frames for semiconductors, as well as for cable connectors and for the central fuse, relay and terminal box of automobiles. BB01 is a copper alloy with a low Sn content for power semiconductors, which are used in the case of high heat development (e. g. TO 220). BB01 differs from SB02 (UNS C19400) by the higher thermal conductivity and the higher electrical conductivity. In comparison with pure copper BB01 has a higher strength while the electrical conductivity is a little lower. BB01 has excellent soldering and welding properties. The alloy is registered with the U.S. EPA as Antimicrobial and with respect to Pb and Cd meets the OEKO-TEX Standard 100.

SB01: Low-alloyed copper alloys are distinguished by a high electrical conductivity. They do not reach the spring force of the bronzes, however, in comparison with pure copper, they are significantly harder. Therefore, they are predominantly used for lead frames for semiconductors. SB01 is a copper alloy with a very low iron content. SB01 differs from SB02 (UNS C19400) by the higher thermal conductivity and the higher electrical conductivity. In comparison with pure copper SB01 has a higher strength while the electrical conductivity is a li5le lower. SB01 has excellent soldering and welding properties. The alloy is registered with the U.S. EPA as Antimicrobial and with respect to Pb and Cd meets the OEKO-TEX Standard 100.

SB02: Low-alloyed copper alloys are distinguished by a high electrical conductivity. They do not reach the spring force of the bronzes, however, in comparison with pure copper, they are significantly harder. During the last decade SB02 (UNS C19400) has gained importance for lead frames because of the high electrical conductivity and the favourable price and in the mean- .me it has become the copper alloy with the world-wide most frequent use for this application. Due to the necessary miniaturisation of components and the increased packing density involved, materials with high conductivity gain importance. Therefore, for some .me SB02 is also used in electric and electronic automotive applications for special connectors and for the central fuse, relay and terminal box. The alloy is registered with the U.S. EPA as Antimicrobial and with respect to Pb and Cd meets the OEKO-TEX Standard 100.

Material designations of BB01 | SB01 | SB02

| Material designations | |||

| Sundwiger | BB01 | SB01 | SB02 |

| DIN-EN Symbol | CuSn0,15 | CuFe0,1P | CuFe2P |

| DIN-EN | CW117C | – | CW107C |

| UNS | C14415 | C19210 | C19400 |

| JIS | C1441 | C1921 | C1940 |

Nominal composition of BB01 | SB01 | SB02

| Nominal composition (mass content in %) | |||

| Sundwiger | BB01 | SB01 | SB02 |

| Cu | Balance | Balance | Balance |

| Sn | 0,12 | – | – |

| Fe | < 0,02 | 0,1 | 2,4 |

| Ni | < 0,02 | – | – |

| Zn | < 0,1 | – | 0,13 |

| Pb | < 0,005 | – | < 0,005 |

| P | < 0,015 | 0,03 | 0,03 |

| Other | – | < 0,1 | < 0,1 |

Processing instructions of BB01 | SB01 | SB02

| Processing instructions | |

| Cold forming properties | very good |

| Machinability | sufficient |

| Electroplating properties | very good |

| Hot-dip tinning properties | very good |

| Soldering | very good |

| Resistance welding | good |

| Gas shielded arc welding | good |

| Laser welding | good |

Physical properties of BB01 | SB01 | SB02

| Physical properties (at room temperature) | ||||

| Sundwiger | BB01 | SB01 | SB02 | |

| Electrical conductivity soft | 48 | 49 | 36,5 | MS/m |

| Thermal conductivity | 360 | 430 | 260 | W/(m*K) |

| Thermal expansion coefficient between 20 and 300 °C | 17 | 17 | 17 | 10-6/K |

| Density | 8,9 | 8,9 | 8,9 | g/cm³ |

| Modulus of elasticity | 128 | 125 | 123 | GPa = kN/mm² |

We advise you on our fine alloys

Call us or write to us, we will be happy to advise you personally!

Contact Form

Write to us, we would be happy to advise you personally!