Nickel silver strip and semi-finished product manufacturer

We offer bands in 9 different nickel silver alloys.

Strip product: Buy nickel silver strip and semi-finished products from Germany

Applications of nickel silver alloys NB12 – NB18 | NX02 | NX05 | NX13

Typical applications

- Coins

- Caps for crystals

- Electromagnetic shielding

- Deep drawn parts

- Tableware

- Security keys

- Cutlery

- Contact springs

- Connectors

- Relay springs

- Electrical contacts

Coppe-base-alloys

Available dimensions of nickel silver strip

- Bright pre-rolled strip

1,0 – 5,0 mm - Precisions strip thicknessess

0,07 – 1,2 mm - Strip widths

3,0 – 600 mm,

but at least 10 times strip thickness

Nickel silver alloys NB12 – NB18

Nickel silver alloys and semifinished products NX02 | NX05 | NX13

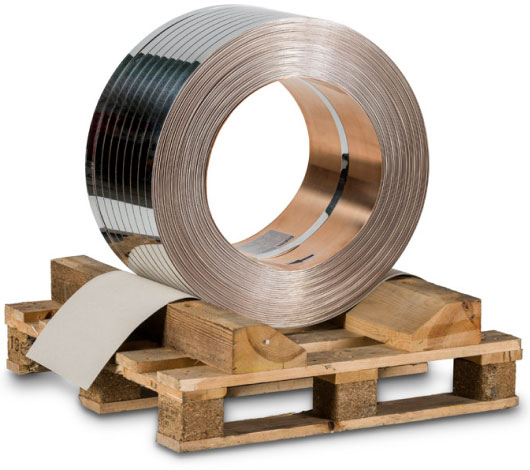

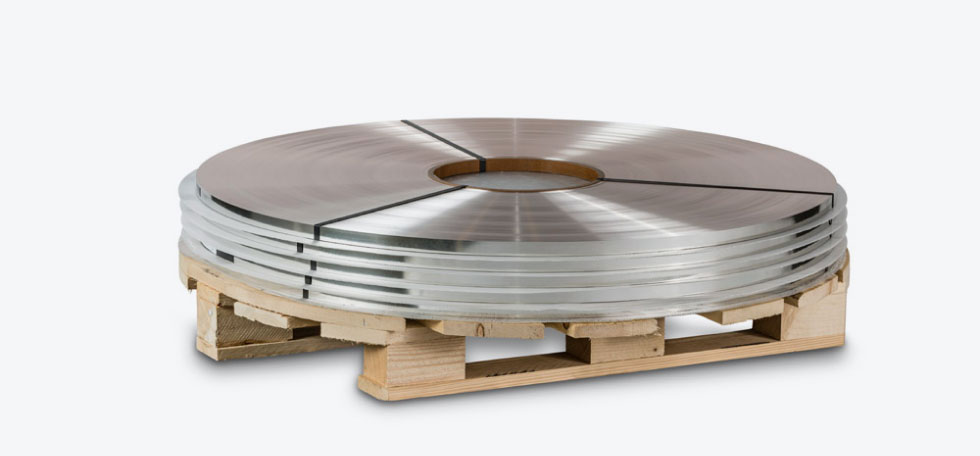

Nickel silver ribbon in various presentations directly from Sundwiger Messingwerk

The delivery form of our products depends on the technical facilities of our customers. Three basic designs are available here. These are each adapted to the equipment available at our customers.

The most used form are coils. Here, the individual coils are stacked on pallets, usually separated by spacers.

In the spooled version, several coils are wound in one spool. The coils are connected with help of a weld seam. In this way, set-up times can be saved in the subsequent process steps.

Multiple Pancake

Multiple pancake is a special form of coil design. Here, the individual coils are connected alternately at the inner and outer windings by weld seams. The created “endless strip” can be unwound directly from the pallet on turntables.

Nickel silver band FAQ: Frequently asked questions about our nickel silver alloys

What are the special features of the materials NB12 - NB18?

NB12 is a nickel silver alloy which is alloyed with 12% nickel and 24% zinc. It is easy to cold-form and has particularly good deep-drawing properties. Like all copper materials, the copper-nickel-zinc alloys show no tendency to embrittlement at lower temperatures. The corrosion resistance of nickel silver is much better than that of binary copper-zinc alloys. NB12 is insensitive to stress corrosion cracking. NB12 is used for contacts, deep drawn parts and for optical goods. This alloy is registered with U.S. EPA as antimicrobial.

NB15 is a nickel silver alloy, which is alloyed with 18% nickel and 10% zinc. It is particularly good at cold working and has exceptionally good deep drawability. Like all copper materials, the copper-nickel-zinc alloys show no tendency to embrittlement at lower temperatures. The corrosion resistance of nickel silver is much better than that of binary copper-zinc alloys. NB15 is insensitive to stress corrosion cracking. NB15 is used for deep drawn parts and for optical goods. This alloy is registered with U.S. EPA as antimicrobial.

NB17 is a nickel silver alloy, which is alloyed with 18 % nickel and 27 % zinc. It has good cold working properties, is tarnish resistant and has particularly good spring properties. Like all copper materials, the copper-nickel-zinc alloys show no tendency to embrittlement at lower temperatures. The corrosion resistance of nickel silver is much better than that of binary copper-zinc alloys. NB17 is insensitive to stress corrosion cracking. NB17 is used for contact springs in relays, shielding and jewellery.

NB18 is a nickel silver alloy alloyed with 18 % nickel and 20 % zinc. It has good cold working properties, is tarnish resistant and has very good spring properties. Like all copper materials, the copper-nickel-zinc alloys show no tendency to embrittlement at lower temperatures. The corrosion resistance of nickel silver is much better than that of binary copper-zinc alloys. NB18 is insensitive to stress corrosion cracking. NB18 is used for contact springs in relays, shielding and jewellery.

What are the special features of the materials NX02 | NX05 | NX13?

NX13 – a special nickel silver – is mainly used for security keys. It is preferred for key production because of the following properties:

- Excellent punchability and good embossability

- Particularly good machinability

- Optimum strength properties

- Very good corrosion resistance

Depending on the customer’s requirements or application, we produce NX13 in the delivery states HB160 and HB170; other hardness levels can be supplied on request.

Material designations of NB12 - NB18

| Material designations | ||||

| Sundwiger | NB12 | NB15 | NB17 | NB18 |

| DIN-EN Symbol | CuNi12Zn24 | CuNi18Zn10 | CuNi18Zn27 | CuNi18Zn20 |

| DIN-EN | CW403J | – | CW410J | CW409J |

| UNS | C75700 | C73500 | C77000 | ≈ C 76400 |

| JIS | – | C7351 | C7701 | C7521 |

Material designations of NX02 | NX05 | NX13

| Material designations | |

| Sundwiger | NX13 |

| DIN-EN Symbol | CuNi12Zn25Pb1 |

| DIN-EN | CW404J |

| UNS | C79200 |

| JIS | – |

Processing instructions of NB12 - NB18

| Processing instructions | |

| Cold forming properties | very good |

| Machinability | satisfactory |

| Electroplating properties | very good |

| Hot-dip tinning properties | satisfactory |

| Soldering | satisfactory |

| Resistance welding | very good |

| Gas shielded arc welding | good |

| Laser welding | good |

We advise you on our nickel silver base alloys

Call us or write to us, we will be happy to advise you personally!

Contact Form

Write to us, we would be happy to advise you personally!